Product Description

High Purity Slicon carbide with CAS 409-21-2

Product Overview

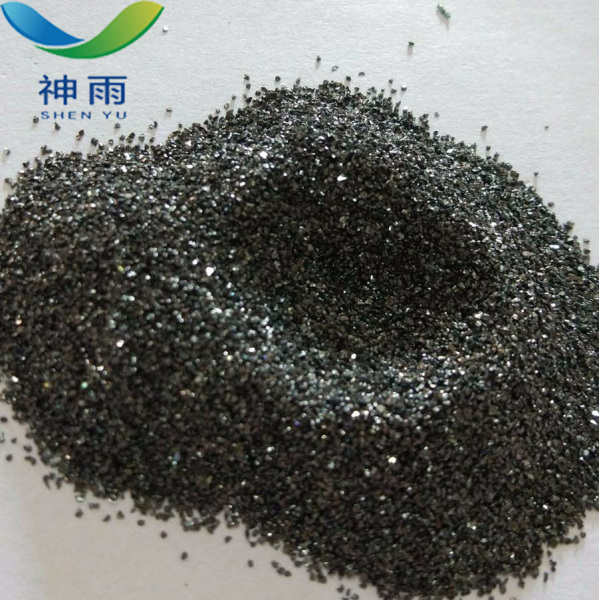

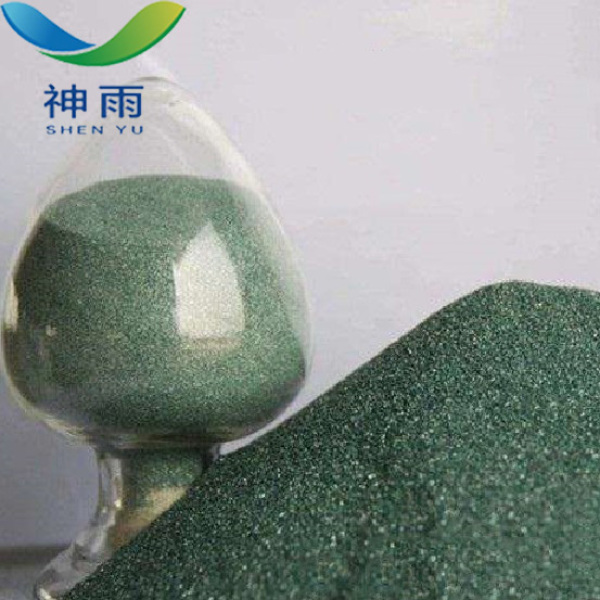

Silicon carbide is a non-metallic carbide that is covalently bonded by silicon and carbon, and its hardness is second only to diamond and boron carbide. The chemical formula is SiC. A colorless crystal that is blue-black when the surface is oxidized or contains impurities. Silicon carbide variants with a diamond structure are commonly known as corundum. The hardness of corundum is close to that of diamond, and its thermal stability is good. It is converted from β-silicon carbide to α-silicon carbide at 2127 °C, and α-silicon carbide is still stable at 2400 °C. It is stable to aqueous hydrofluoric acid solution and concentrated sulfuric acid, and is unstable to mixed acid or phosphoric acid of concentrated hydrofluoric acid and nitric acid. It is decomposed by the molten alkali in an empty atmosphere. It is divided into synthetic silicon carbide and natural silicon carbide.

Physical Properties

CAS No.: 409-21-2

Molecular formula: CSi

Molecular weight: 40.1

EINECS number: 206-991-8

Melting point 2700 °C (lit.)

Density 3.22 g/mL at 25 °C (lit.)

Refractive index 2.6500

Soluble in molten sodium hydroxide, potassium hydroxide and in molten iron.

Morphology nanopowder

Color Green

Application

It is widely used in atomic energy materials, chemical devices, high temperature processing, electric heating originals and resistors due to its high thermal stability, high strength and high thermal conductivity. Used in abrasives, abrasives, advanced refractories, fine ceramics.

Used in abrasives, anti-wear agents, abrasive tools, advanced refractory materials, fine ceramics.

Suitable for the manufacture of silicon carbide abrasives and ceramic kiln furniture for various purposes, as well as refractory materials, etc.

It can be used as a reinforcing fiber for composite materials such as resin and metal, and can also be used as a radio wave absorbing material and a heat resistant material.

Used as a reinforcing material for composite materials, it acts as an isotropic reinforcement. Composite materials with plastics, metals, and ceramics can improve various properties. It can be combined with thermoplastic and thermosetting resins to significantly improve the strength, modulus of elasticity, thermal conductivity and wear resistance of plastics. Adding 15% silicon carbide whisker to PEEK, the thermal conductivity is improved by about 2 times, and the flexural strength of polyimide reinforced with 20% silicon carbide is increased by about 2 times at room temperature, at a high temperature of 250 ° C and at normal temperature. The same is true for unenhanced situations. When 15% silicon carbide was added to the epoxy resin, the amount of wear was reduced by 17%.

Abrasive. High temperature resistant materials. Manufacturing high-purity single crystals and semiconductors.

Other related items of our company:

1. Basic Organic Chemicals

2. Inorganic Chemicals

3. Pharmaceutical Intermediates

4. Daily Chemicals

5. Active Pharmaceutical Ingredients

.png) Contact Now

Contact Now